Colon Towers

Introduction

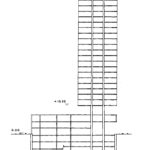

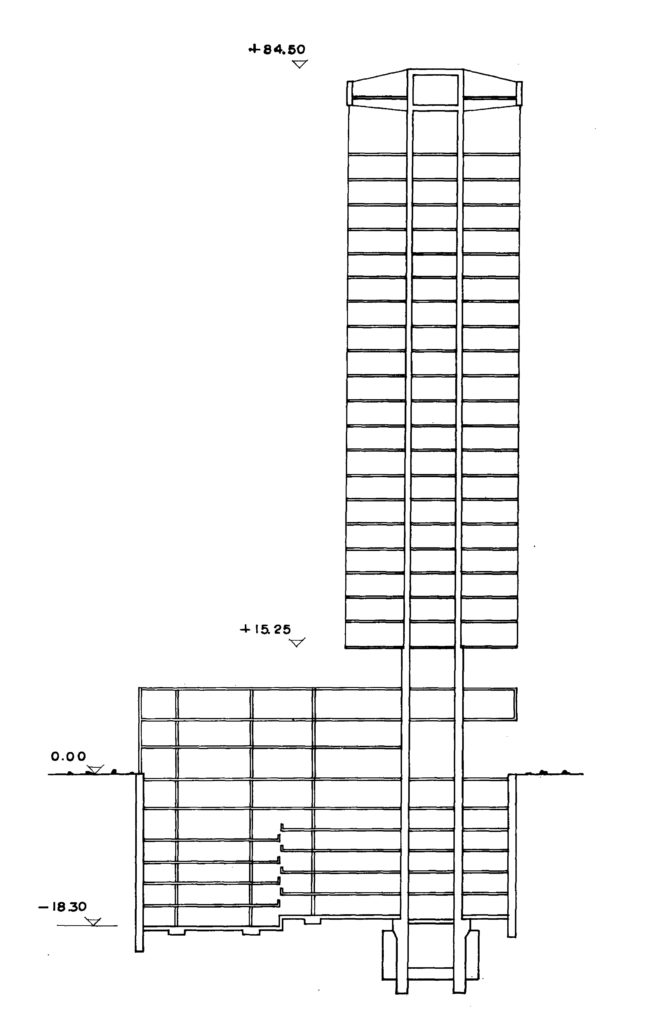

Colon Buildings, also known as Torres de Colón, is located on the northwest corner of Colon Square in Madrid, next to Castellana and Genova streets. It consists of three different volumes: the underground part of the building has 6 basements, 3 floors in the surface, and the two twin towers of 21 floors. The total height above the ground is 110 m, while it has 24.75 m below it. The basements and the intermediate plants occupy the entire surface of the plot, of around 1,700 m2, while the two towers occupy an area of about 700 m2.

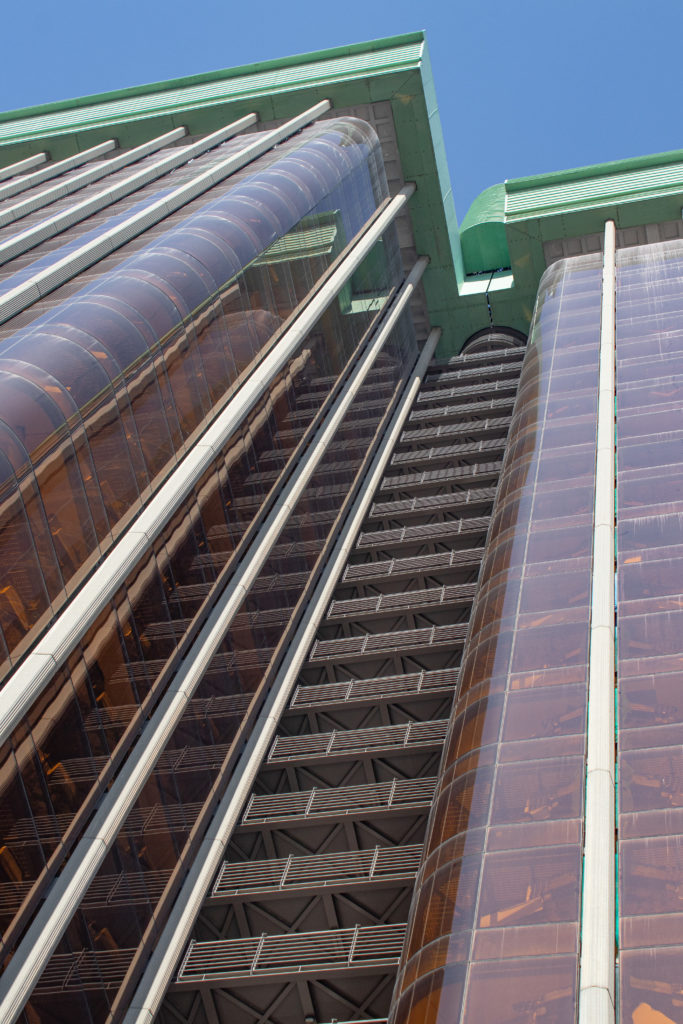

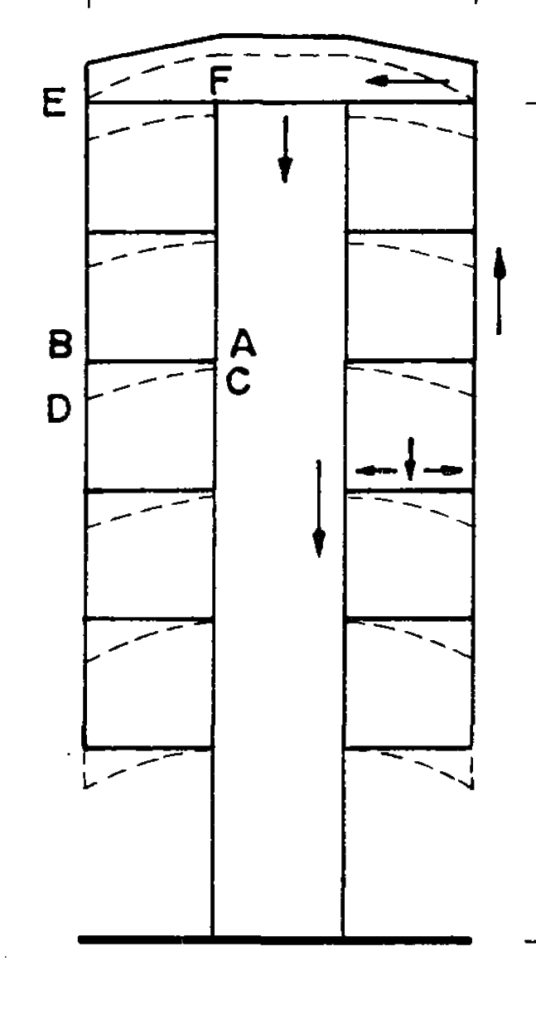

The main feature of the building is its structure and how it was built. This type of buildings is called “hanging buildings,” as the floors do not rest on the columns but hang from them. The head of the towers, located at the top, collects the loads coming from the columns to transfer them to a concrete central core. This core runs all the way down until the foundation, where it transfers the loads to the ground.

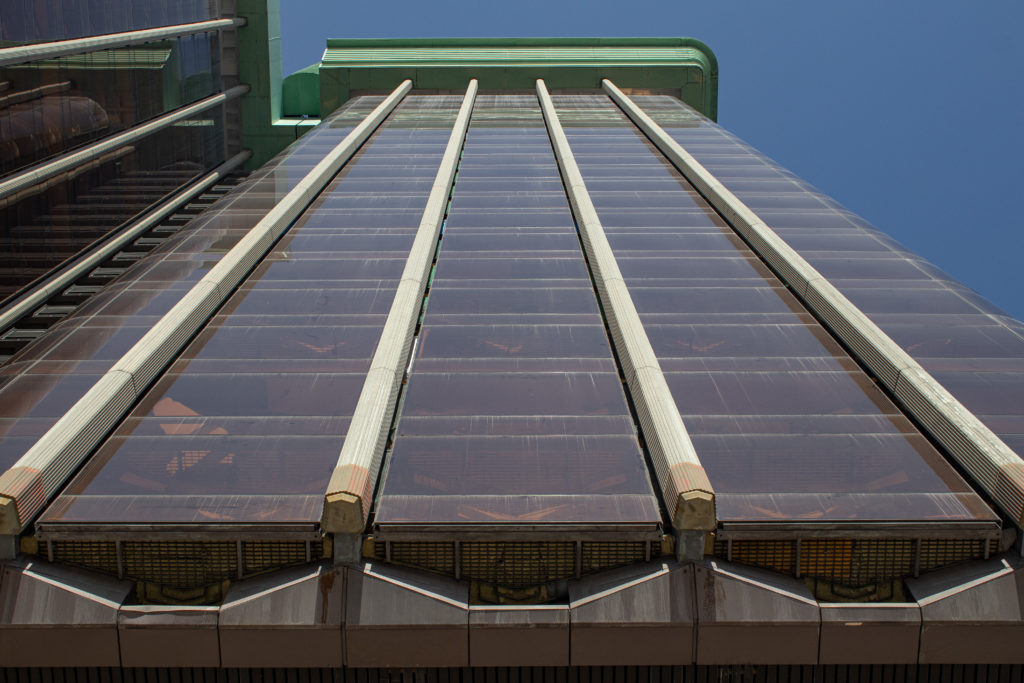

In 1990, the new evacuation in case of fire laws obliged the owners to install an external emergency staircase that was placed between the two towers. In order to hide utilities and machinery, they topped the stairs with a significant art-deco element in green bronze, colloquially called “the plug.” Also, during the rehabilitation works, the facades were changed. They were initially built as anodized aluminum sheets with a bronze color and were transformed into a double skin facade with new colored glass to improve energy control.

Behind this great project, there is much to learn.

Historical overview

Madrid City Council asked for “an architectural unit with a remarkable verticality” to be built at Colon Square’s plot. Lamela Architects were in charge of the project, and they proposed the execution of two non-aligned towers instead of a bigger single one, a design more in line with the rest of the city.

The conflict between a traditional structure with columns and the larger spaces required in the basement floors dedicated to parking defined the unique structure of the building.

The construction project of the building was finished in 1968, and construction began in 1969. In July 1970, the mayor of the city, Carlos Arias Navarro, ordered to stop the works claiming that the Towers were 9 meters higher than what was allowed. At that moment, the cores and half of the top platform (element responsible for collecting all the loads and transferring them to the cores) were completed. The promoter, José Osinalde, appealed the sentence, and three years later, the Court’s judgment ruled in his favor. Demolition was almost carried out, as even a demolition project was executed. The towers were intended to be used as residential buildings but, in order to economically compensate the property for the damages caused, they became office buildings, which can be sold at a much higher price.

The works resumed in 1973, with some engineering problems such as a big beam executed in two phases. Engineers had to deal with concretes of different ages, shrinkage, creep, and environmental effects.

It was finally inaugurated in 1976 as the tallest building in Madrid, record hold until the Picasso tower was finished in 1989. Right after completed, Osinalde sold Colon Towers to the group of companies Rumasa, own by Ruiz-Mateos.

Concept

The concept of the building, with its “suspended or hanging structure,” comes from the need to coordinate and organize the spaces of the floors above ground and the parking floors. Therefore, it was decided to design a structure with a unique bearing element: a central core.

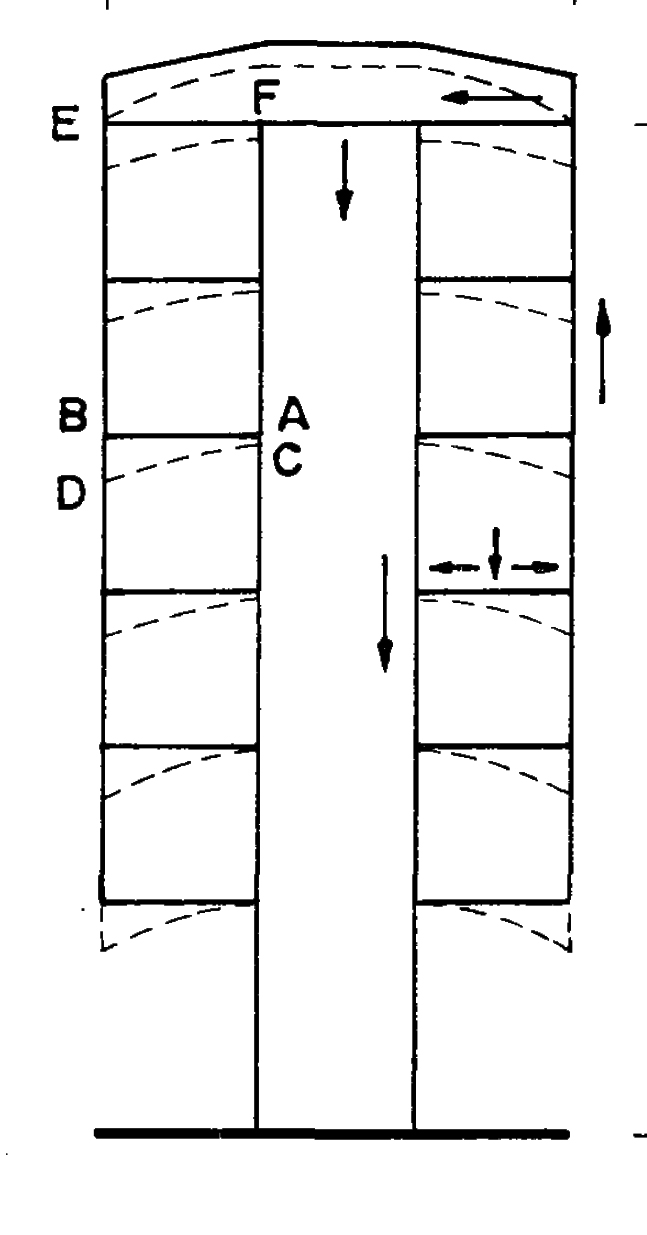

The standard structure of a building is based on the fact that the floors are supported by columns that transfer the load to its foundations and from there to the ground. In a “suspended building,” the floor slabs are supported by hangers that transfer the load to a platform at the head of the building. From there, the loads go to a central core, which is the only element having a foundation and, therefore, the only one supporting the building. It should be noted that part of the floor loads do not scale through the hangers but move straight to the central core, where each floor is also supported.

If the floors end up cantilevering from the core, the structure would be inefficient and more expensive. So, the efficiency of the hanging system depends on several factors.

- The stiffness of the upper platform, which has to be much higher than the flexural stiffness of the slabs, for its deformation not to decrease the hanging effect.

- The relationship between the height and the width of the building. We can picture the support on the hangers as a spring. The longer the spring, the less rigid it is. This means that the support of the lower floors is less rigid than that of the upper ones. Also, the spring stiffness is less the higher the number of hanging plants is. In addition, the narrower the building, the higher cantilever capacity will have the slabs, as they are spanning a smaller space. So, the lower and wider the building, the better the hanging system will behave. The Colon Towers have a hanged height / hanged width ratio of 3.3. As a reference, a value of 4 would be the upper limit for correct performance.

- Floor-core connection. This connection may be fixed or simply supported. When fixed, the stiffness of the floor will considerably influence the efficiency of the hanging system, as already mentioned. If the slab is simply supported, the hanger will (yes or yes) carry its tributary area load. Colon Towers slabs are in an intermediate situation. They are simply supported and built as continuous elements, so there will be a certain fixing effect around the core.

Structural design

Colon Towers are composed of four elements: the central core, the head or hanging platform, the hangers, and the floor slabs.

Core

The core dimensions are 7 x 6.80 m, with 0.6 m thick walls. There are seven openings per floor for the doors. Vertical circulations of the building are developed in the interior of the core.

An advantage of this type of buildings is the great compression in the base of the core coming from the permanent loads, which helps to withstand the bending due to lateral loads such as wind loads.

Platform

As it’s been stated, the platform has to be a stiff structure for the “hanging building” system to work properly. It consists of 8 cantilever beams aligned with the core walls. They are 60 cm wide, and its height increases from 3 m to 5 m when reaching with the core. They are joined by four edge beams located on the perimeter of the building. The hangers are anchored to them. These edge beams are 50 cm wide and 3 m high. All beams are prestressed elements. The last part of the head is a 25 cm thick slab that was lightened with hollow plastic boxes, and on top of which building utilities were placed.

Hangers

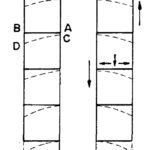

We can first think that since the hangers work in tension, they should be made out of steel. However, Colon Towers hangers’ material is prestressed concrete, which results in cheaper elements with the same stiffness, while matching its behavior to the concrete core’s. The pre-compression force is high enough to avoid tension under the permanent load hypothesis.

The hangers are 42 X 42 cm, they have an interior hole of 27 x 10 cm for the prestressing cables to pass through, and the distance between hangers is 3.6 m.

Floor slabs

The typical floor consists of a 25 cm thick concrete slab lightened with hollow plastic boxes. It is continuous and rests on the core employing steel corbels, located in the corners and midpoints of the walls.

As it is already said, the lower the level of the floor, the less efficient is its support on the hangers. So the reinforcement of the slabs in the lower levels is higher since they have to deal with higher forces at the connection with the core. The set of slabs was divided into three equal reinforcement packages of 7 floors each.

The connection between the slabs and the hangers utilizes two vertical steel plates coming out from the hangers welded to two other vertical plates attached to the slab.

Construction process

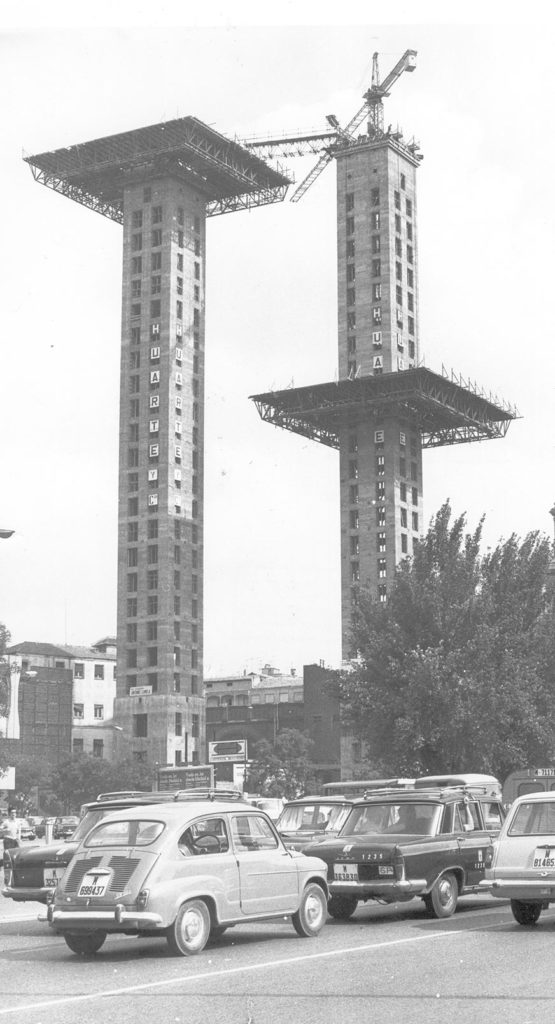

First, they built the cores using a climbing formwork to place the concrete. Steel plates connected to the concrete were left to weld them later on to the steel corbels where the floors would be supported.

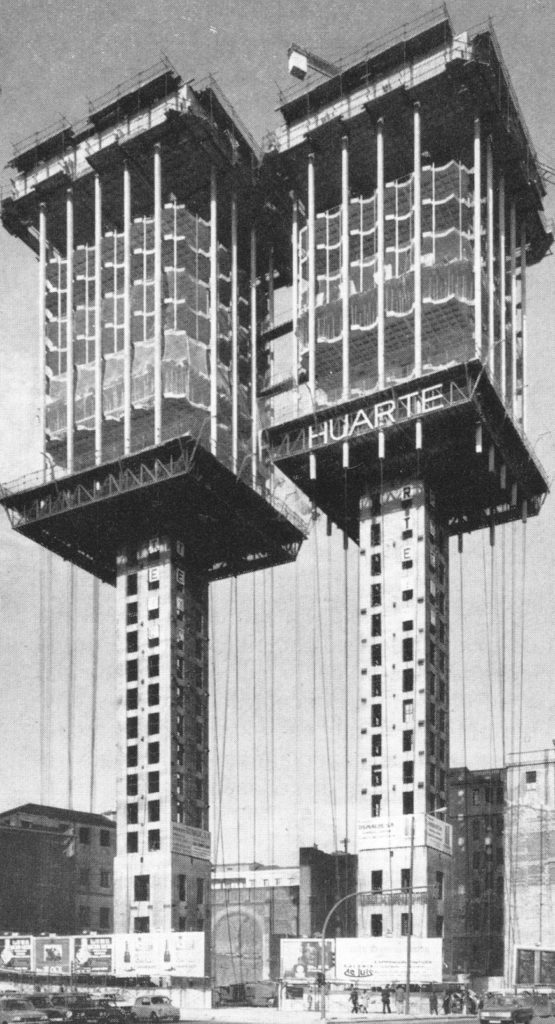

Afterward, the construction process that attracted the attention of both Madrid and tourists tried to follow the saying “building the house from the roof.”

The head was built next. It was necessary to construct two large steel formworks and put them in place. They used jacks to raise them to the top of each tower. It was decided, in order to reduce costs and material, to design the formworks to resist the weight of a typical floor. Since the weight of the head was much higher, it was necessary to place the concrete in different phases:

- Concrete pouring of the lower half of the cantilever beams supported by the formwork.

- Concrete pouring of the upper half, supported by the already hardened lower part and the formwork.

- First prestressing of the cantilever beams.

- The steel formworks were hanged at the end of the cantilever beams.

- Concrete pouring of the lower half of the edge beams supported by the formwork and cantilever beams.

- Concrete pouring and prestressing of the rest of the beams. It was done in three phases, as load increased due to the construction of floors.

After the head was completed, the steel formwork started to go down to build the floors. Workers used the formwork for pouring the concrete one every two stories. Traditional construction was used for the slabs in between, this is, concrete is poured on traditional formworks supported on the already hardened slab below. That way, construction speed was much faster.

The hangers were prefabricated with a length equal to the height of two floors (5.9 m), and only the part attached to the head is 6.15 m long. The hangers were lifted to their final position using a single-strand prestressing jack. They were preloaded from the top of the head in two stages. Once all the floors were hung, the internal holes were injected with concrete to protect the steel.

Concrete for the slabs was placed in circles around the core, starting from it. Final steps consisted of pouring the area on top of the steel cantilevers (joint between slabs and core), and welding the steel plates connecting the floors with the hangers, also protecting them with concrete. Before welding, these plates could slide during construction until all the levels were finished.